Petroleum coke, commonly referred to as pet coke, stands as a distinctive carbon-rich byproduct derived from refining processes within the petroleum industry. This resource has found a place in various industrial sectors due to its unique composition and versatile applications.

Pet coke’s formation occurs during the refining of crude oil, where residual hydrocarbons are subjected to thermal processes that result in the creation of a solid carbonaceous material. This material holds notable calorific value, making it a sought-after fuel source for industries requiring high-energy input, such as cement production and power generation.

Characterized by its high carbon content and low ash content, pet coke delivers efficient and consistent combustion performance. Its application extends to steelmaking, where it serves as a cost-effective fuel alternative in blast furnaces, contributing to high-temperature processes and iron production.

Moreover, pet coke’s industrial applications encompass the production of anodes for the aluminum industry, where its electrical conductivity and robustness play a critical role in the electrolytic process. Additionally, pet coke’s carbon-rich nature finds use in specialized industrial processes, such as graphite production and carbon electrode manufacturing.

However, it’s essential to note that pet coke’s usage has raised environmental concerns due to its emissions profile. The combustion of pet coke can release higher levels of greenhouse gases and other pollutants compared to other fuels. As such, there is an ongoing debate about balancing its industrial benefits with environmental impacts and sustainability.

In essence, petroleum coke reflects the intricate interplay between industry, energy, and environmental considerations. Its unique composition, wide-ranging applications, and associated challenges underline its significant presence in modern industrial processes while prompting discussions about optimizing its usage within a sustainable framework.

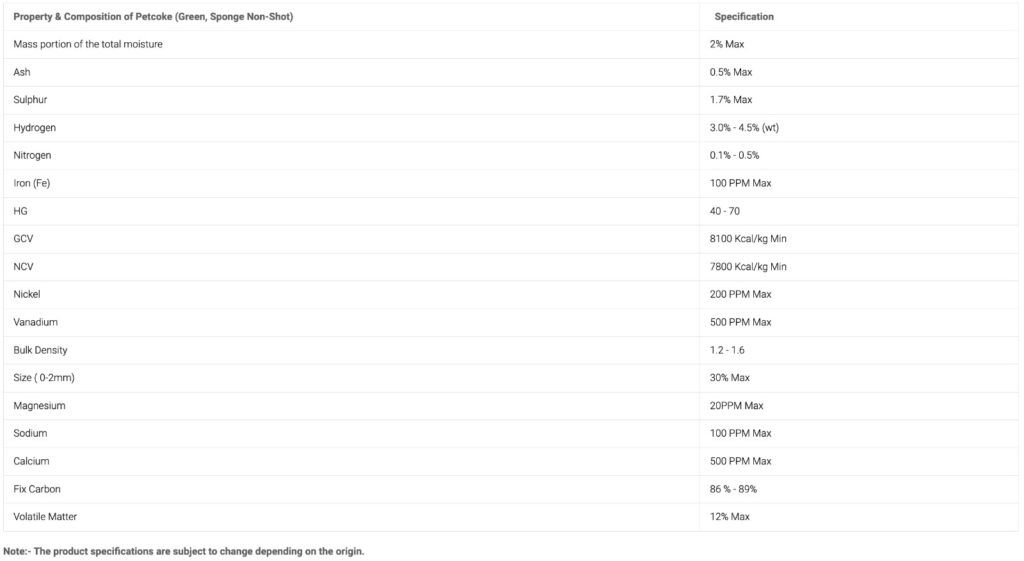

Product Specifications